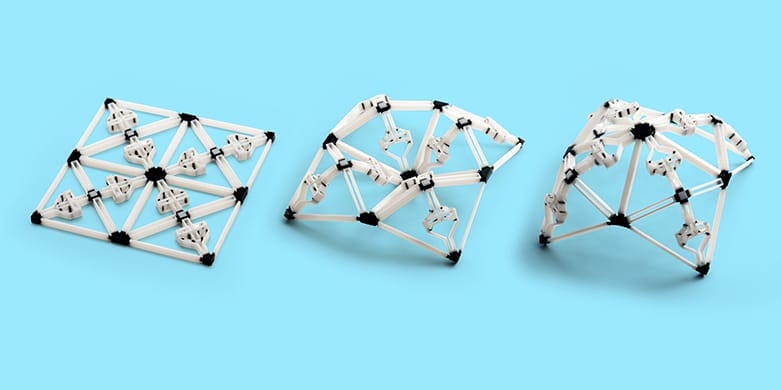

Soft robotics has long promised machines that are safer, lighter, and more adaptive than their rigid industrial counterparts. Yet the field has been slowed by practical constraints: heavy pneumatic pumps, external tubing, and limited modes of movement. Researchers at the Singapore University of Technology and Design (SUTD) believe they have found a way forward with a deceptively simple innovation. Their “FiBa” modules—short for film-balloon actuators—combine curved polymer films with 3D-printed balloons to create lightweight, flexible units that can power a new generation of untethered robots.

The FiBa breakthrough, published in Science Robotics in July 2024, is not just a story about clever engineering. It is also a story about design—specifically, the translation of biological strategies for movement into mechanical form. By looking to turtles, inchworms, bats, and ladybugs, the Soft Fluidics Lab at SUTD has turned animal motion into a blueprint for robotic locomotion.

Material Simplicity, Structural Intelligence

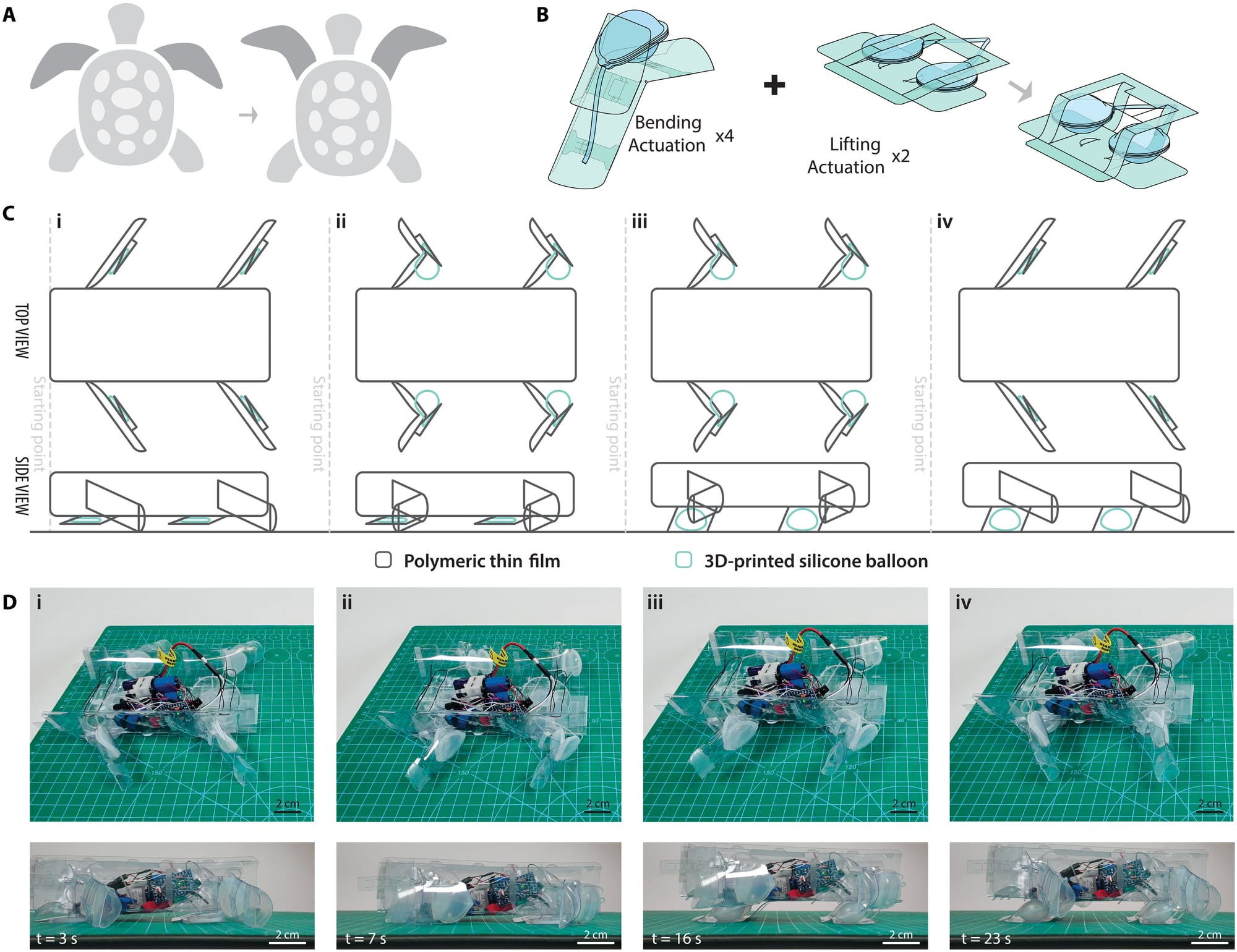

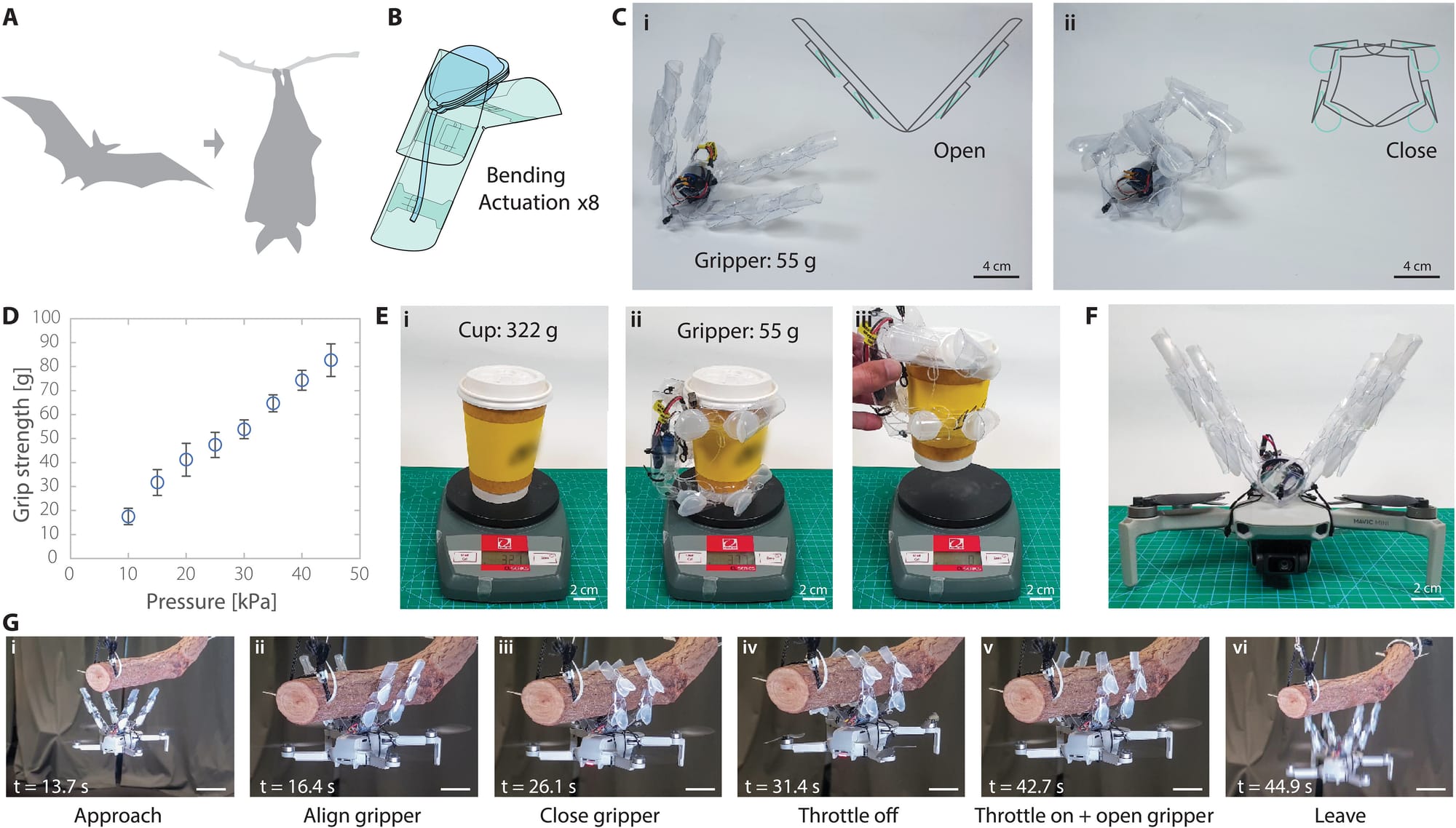

At the heart of the FiBa module is a combination that is as accessible as it is effective. A thin polymer film is curved transversely, echoing the spring-like structure of a carpenter’s tape measure, and paired with a compact pneumatic balloon. When pressurized, the balloon pushes against the film to produce movement. This design allows the actuator to generate strength and flexibility while remaining exceptionally light. Because the modules weigh so little, they can carry onboard pumps, valves, batteries, and controllers. In practice, this removes the need for external tubing and tethered power supplies, a long-standing bottleneck for soft robotics.

What emerges is a system that is not only functional but autonomous. While many robotics breakthroughs are driven by advances in computation, FiBa demonstrates how structural and material design can also provide solutions.

Biomimicry in Motion

Rather than showcasing the modules in abstract movements, the research team turned to nature. A crawling robot drew inspiration from the low, stable gait of a turtle, designed to illustrate steady progress across flat surfaces. Another prototype climbed in the looping rhythm of an inchworm, revealing how contraction and extension could carry a robot vertically. A third design perched on ledges with the stability of a bat, showing how soft structures can maintain position in static environments. The most ambitious of the group unfolded like a ladybug, deploying hidden wings mid-air to achieve controlled flight. Each of these movements underscored a different dimension of the FiBa’s potential, illustrating how biological strategies for efficiency, adaptability, and protection can be translated into robotic performance.

The ladybug design in particular shows how compactness and adaptability can be combined. On the ground, the robot remains small and protected, but once airborne it expands into a flyer. Nature’s own solution—hardened wing covers concealing delicate flight wings—proved a useful model for balancing resilience with functional mobility. The takeaway for soft robotics is that reconfiguration, rather than fixed form, may be one path to versatility.

From Laboratory Prototype to Potential Applications

The FiBa modules are still in the early stages of research, but their implications are broad. A robot that can crawl, climb, perch, and fly without external hardware points toward future applications in environments where traditional machines often fall short. In disaster response, lightweight climbers or crawlers could one day move through rubble to locate survivors without the encumbrance of cables. In healthcare, perching or soft-bodied devices might operate safely around humans, reducing the risks posed by rigid machinery. In aerospace, compact robots that deploy larger structures when needed align with the priorities of space engineering, where weight constraints are critical.

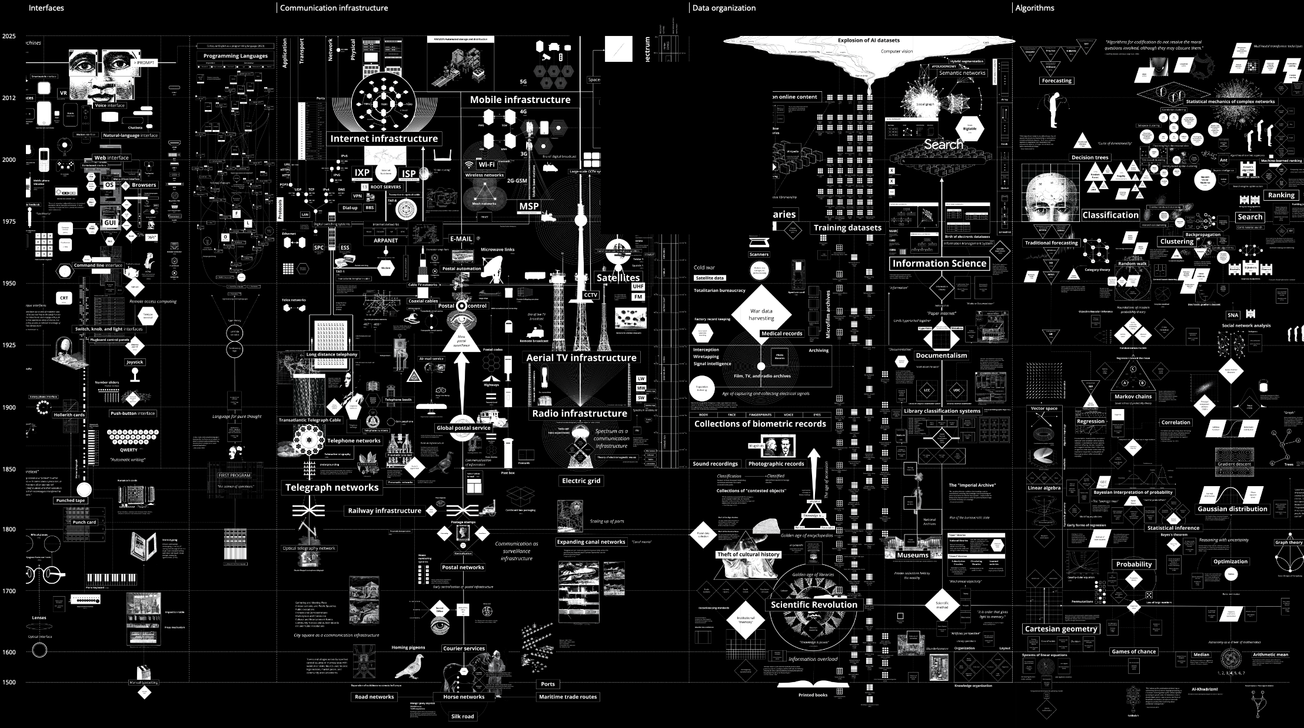

These scenarios remain speculative, but they highlight the kinds of domains where FiBa’s lightweight autonomy could matter. Just as importantly, the project suggests a way of reframing robotics development as a material problem rather than a purely computational one. Instead of relying on algorithms to compensate for mechanical limitations, the FiBa modules embody solutions directly in their physical design. This perspective positions robotics closer to design disciplines, where form and material choice are recognized as central to function.

A Design Language for Soft Robotics

The FiBa initiative is the product of collaboration across institutions, led by Dr. Terry Ching during a joint PhD between SUTD and the National University of Singapore, with Professor Michinao Hashimoto of SUTD’s Soft Fluidics Lab as a corresponding author. The work also involved the Aerial Innovation Research Lab at SUTD and the MicroTE Laboratory at Queensland University of Technology. This interdisciplinary collaboration—spanning fluidics, aerial mechanics, and fabrication—underscores that no single discipline holds all the tools needed to advance soft robotics.

Since its publication in 2024, no major public updates have emerged from the project, indicating that FiBa remains a foundational proof of concept. Yet even at this stage, it points to how robotics might evolve. The research demonstrates that autonomy does not always require heavy infrastructure, and adaptability can be achieved through material ingenuity. By borrowing strategies from nature, the Soft Fluidics Lab has outlined what could become a new design language for robotics—one where intelligence is as much about structure as it is about code.