While still a relatively new technology, 3D printing has a vast, varied, and elaborate history. Originating in the 1980s, 3D printing has evolved from a niche technology to a transformative force shaping industries ranging from manufacturing to healthcare - while becoming a staple in the creative studio.

The concept of 3D printing traces back to the early 1980s when Dr. Hideo Kodama, a Japanese inventor, developed one of the first rapid prototyping machines. Kodama's invention laid the groundwork for additive manufacturing, a process that builds objects layer by layer from digital designs. Shortly thereafter, in 1986, Chuck Hull, an American engineer, patented stereolithography (SLA), a 3D printing technique that uses a UV laser to solidify layers of resin to create intricate three-dimensional objects.

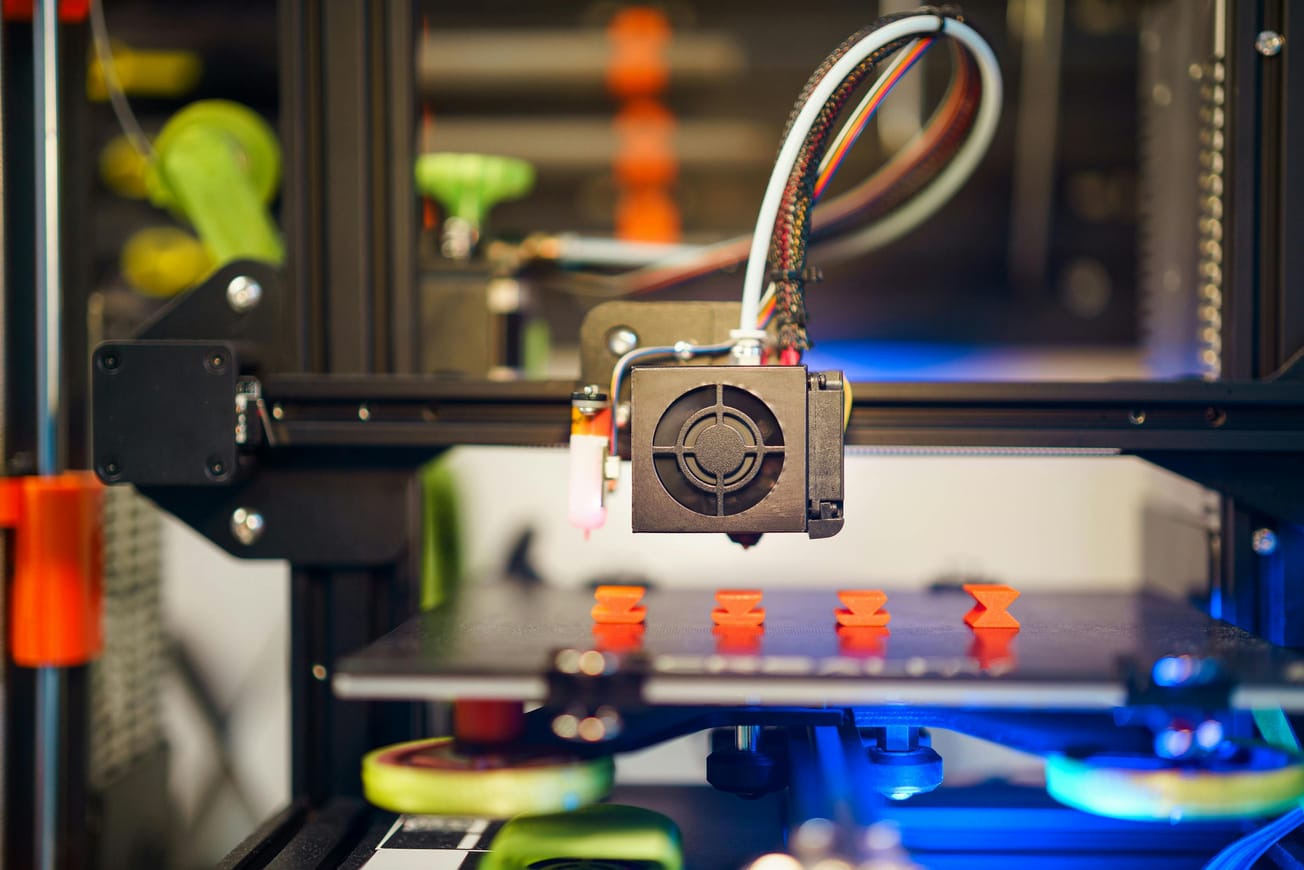

The late 1980s and early 1990s saw a flurry of activity in the 3D printing space, with the emergence of several key technologies and players. In 1988, Carl Deckard, a student at the University of Texas, developed selective laser sintering (SLS), another additive manufacturing process that uses a laser to fuse powdered materials together to form objects layer by layer. That same year, Hull founded 3D Systems Corporation, which released the SLA-1, the world's first commercial 3D printer.

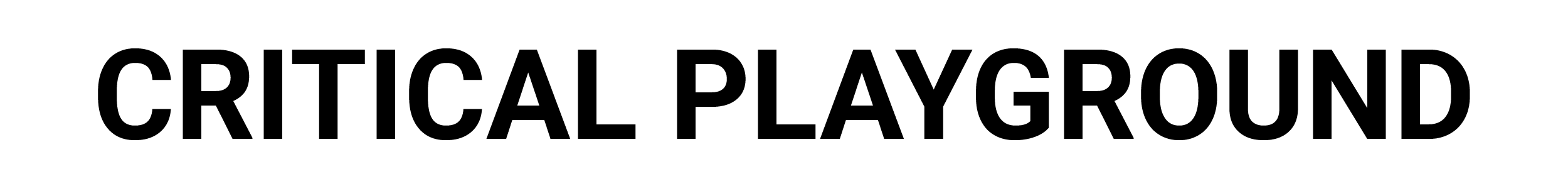

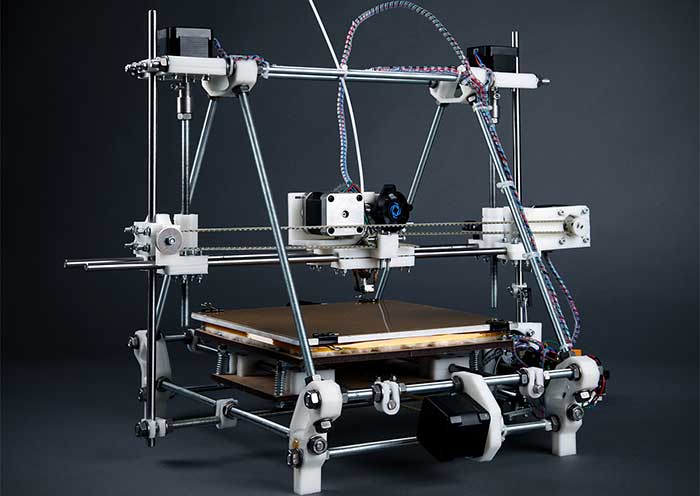

Throughout the 1990s, 3D printing continued to gain traction, fueled by advancements in technology and a growing interest from industries seeking innovative manufacturing solutions. In 1992, Stratasys, founded by Scott Crump, patented fused deposition modeling (FDM), a 3D printing technique that extrudes thermoplastic material layer by layer to create objects. FDM quickly became one of the most popular 3D printing methods, paving the way for the democratization of 3D printing technology.

The early 2000s marked a period of rapid expansion and innovation in the 3D printing industry, driven by improvements in printing speed, resolution, and material capabilities. As patents for key 3D printing technologies began to expire, a wave of new companies and startups entered the market, further fueling growth and innovation. Open-source initiatives like RepRap, launched in 2005, played a crucial role in driving down costs and making 3D printing more accessible to artists and designers.

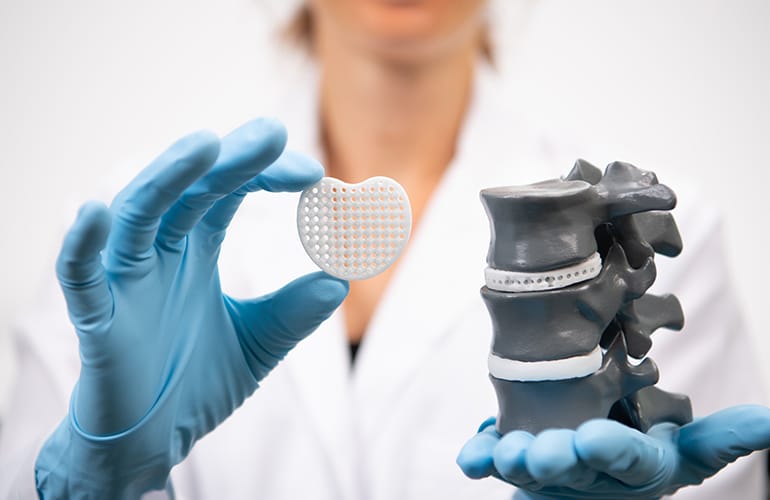

In recent years, 3D printing has continued to evolve and mature, with advancements in materials science, software, and hardware driving new applications and use cases. Today, 3D printing is used across a wide range of industries, from aerospace and automotive to healthcare and design. In aerospace, companies like SpaceX and Boeing use 3D printing to manufacture complex components for rockets and aircraft, reducing costs and lead times while improving performance and reliability. In healthcare, 3D printing is revolutionizing the field of personalized medicine, enabling the production of patient-specific implants, prosthetics, and medical devices.

From fashion, interior, and product design to emergent art practices, access to this technology has had an incredible impact on the trajectory of discourse across the creative fields. Product designers routinely use rapid prototyping to tackle complex geometries while addressing issues of usability and sustainability with material explorations, such as biodegradable polymers and recycled plastics.

Rapid prototyping offers new avenues for experimentation, collaboration, and emergent forms of creative practice. In the last 20+ years, artists have used this technology to hybridize traditional and digital modes of making, subvert the tools and materials of mass production for cultural critiques, and provoke critical reflections on the impact of technology on contemporary society. From construction and architecture to food and electronics, 3D printing has the power to transform industries and reshape the way we design, manufacture, and consume goods, as well as how we explore and unpack the lived human experience.

Based on the ongoing advancements in technology and a growing ecosystem of innovators and entrepreneurs, along with promising new discoveries and breakthroughs on the horizon, it appears probable that 3D printing, as the key rapid prototyping tool, will continue to have a demonstrative impact on the shape of our world.