With increasing affordability and accessibility, could desktop CNCs be the newest addition to the creative studio, complementing the ubiquitous desktop 3D printer?

While 3D printing machines and advanced filament materials have been accessible, to varying degrees, for years, CNC machines have been relatively out of reach for several reasons, including complex machinery and necessary expertise for their operation, calibration, and maintenance. Not to mention knowing how each milling/drilling bit works across an array of materials (woods, plastics, metals, etc). The complexity of operating a CNC machine doesn’t even compare to that of a 3D printer. They aren’t even in the same ballpark.

CNC machining uses computer numerical control (CNC) through software programming to dictate the movement of tools, controlling a range of complex processes and tools, including grinders, lathes, mills, and routers. This subtractive manufacturing process can handle fairly complex three-dimensional cutting processes, removing layers of material with a single set of coded commands.

Enter Consumer-Friendly CNC Machines

Considering the versatile and scalable benefits of desktop CNC machines, integrating a desktop CNC milling machine into your prototyping or small-scale fabrication operations can prove highly practical. These entry-level CNC mills offer the flexibility to craft parts from diverse materials, ranging from wood and foam to softer metals. While mastering CNC milling entails navigating a learning curve involving software and optimizing material/tool combinations (such as speeds and feeds), companies producing desktop versions are beginning to tackle the issue of expertise through additional educational, operational, and community resources.

Due to their precision and consistency, desktop CNC milling machines can be used across creative disciplines and in various modes of making. They excel in post-processing 3D prints, ensuring high tolerances in prototypes. In furniture design, they facilitate digital manipulation of wood, while in self-manufacturing, they offer time and cost efficiency. In art production or one-off creations, CNC milling provides a broader scope for material and surface expression compared to 3D printing.

Factors like machining area, number of axes, and material capabilities are pivotal when selecting a machine. Equally significant is the choice of software and whether it's included in the overall cost. Given its unique advantages, CNC milling yields significant rewards in suitable contexts, making it imperative to align your choice with your specific requirements.

On the Market

Several new desktop CNC milling machines, such as Coast Runner, Rownd, Carvera, and Millennium Mill Milo, have recently entered the market with the goal of enhancing the accessibility and affordability of this technology.

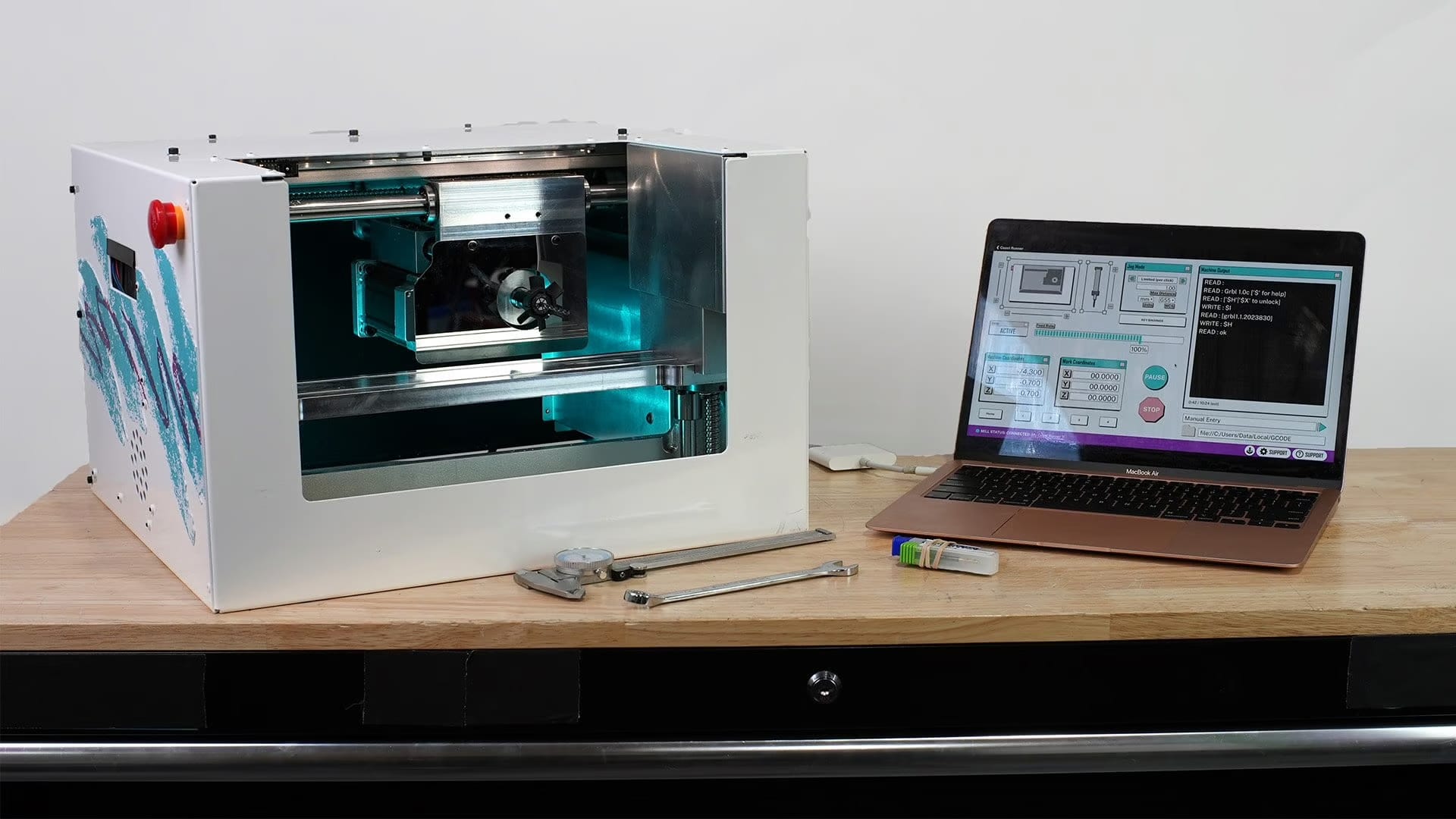

Coast Runner is tackling the issue of expertise by developing educational resources and videos for their users. Moreover, they are concentrating on establishing a network wherein users can hire each other within the community, both for design assistance and for milling parts. In an interview with TechCrunch, Tyler Hoeft “We are making one of the most powerful desktop CNC machines you’ll find in the marketplace. You can cut everything up to titanium. Anything softer is possible: Plastics, brass, hard steel, aluminum, everything.”

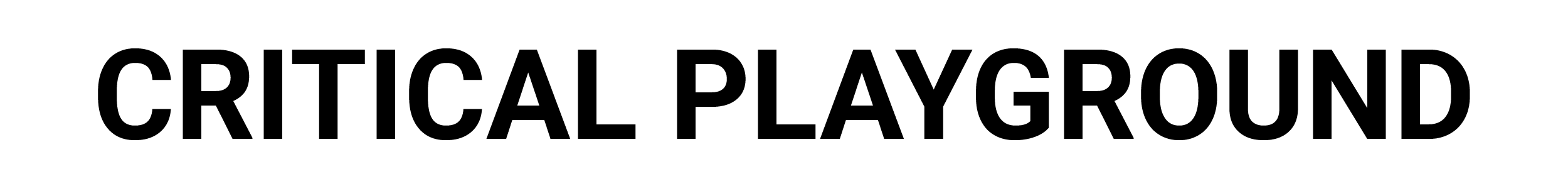

Developed by Designers Ahmet Yasir Karakus and Ahmet Ergun, the Rownd CNC lathe is touted as the “Machine for Everybody.” Funded through a Kickstarter campaign, the company envisions the tabletop lathe as a user-friendly tool for designers, artists, makers, and hobbyists working on small-scale prototyping.

The Carvera Air, also funded through a Kickstarter campaign, is the smaller and far more affordable version of its predecessor, Makera’s original Carvera. The Carvera Air is attempting to solve a series of issues that tend to plague desktop CNC machinery, including the rigidity of the (typically) aluminum frame, the spindle, and the software.

Millennium Mill Milo, a new open-source community project, is a desktop CNC milling machine targeting DYI’ers. The machine is specifically designed for milling aluminum parts. However, it is capable of cutting a range of other materials, including composites, woods, and plastics. Due to the product being open-source there are a number of accessories and add-ons, allowing users to customize their own individual CNC workflow.

The increase in affordable and accessible desktop CNC milling machines in creative production and prototyping is an exciting prospect. Complimenting desktop 3D printers, these machines offer precision, versatility, and growing accessibility as powerful tools for makers, designers, and entrepreneurs. As the market continues to grow, the integration of subtractive CNC processes alongside additive 3D printing will further expand the creative desktop toolkit, for a wide array of applications.