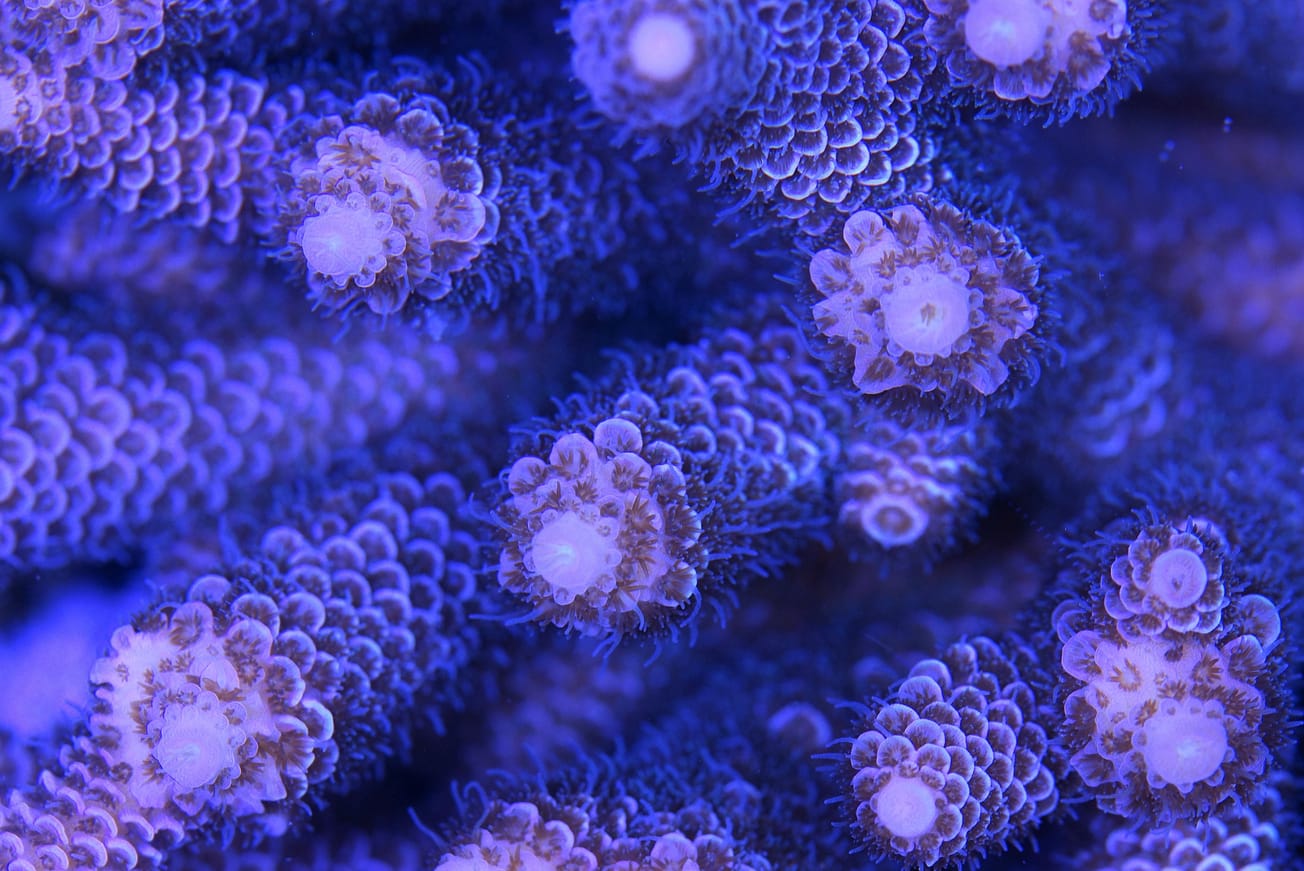

Plastic pollution has become an escalating crisis, casting a shadow over our planet's health and well-being. As plastic waste infiltrates our oceans, soil, and ecosystems, the call for sustainable solutions grows louder. One approach gaining traction is "designing for decomposition," a strategy that emphasizes the end-of-life phase of products and materials in the quest for a circular economy. This approach, which marries design thinking with environmental responsibility, holds the potential to reshape industries and change the trajectory of plastic waste.

In an era marked by technological advancements and innovation, the paradox of plastic waste serves as a poignant reminder of the unintended consequences of unchecked progress. The very materials that have propelled industries forward, providing convenience and efficiency, have also ensnared us in a web of environmental degradation. Plastic waste's detrimental impact on marine life, the alarming accumulation in landfills, and the disheartening images of plastic-choked landscapes have galvanized a collective call for a paradigm shift. The circular economy offers a refreshing departure from the status quo, ushering in an era where materials are valued, utilized, and reintegrated into the production cycle, all while safeguarding the delicate balance of the natural world. Designing for decomposition stands at the heart of this transformation, aligning ingenuity with sustainability and beckoning us toward a future where waste is not an inevitability but an opportunity for renewal.

Designing for decomposition transcends aesthetics and functionality and considers the science of materials and their interaction with the environment. Central to this approach are several guiding principles that lay the foundation for sustainable design:

- Material Selection: The choice of materials is paramount in designing for decomposition. Opting for biodegradable or compostable materials derived from plant sources, like cornstarch or sugarcane, is key. These materials have the remarkable ability to break down into benign components, minimizing their impact on the environment.

- Simplified Design: Complexity can hinder decomposition. Embracing simplicity in design ensures that products can naturally disintegrate without hindrance. This shift often involves refraining from intricate blends and components that can impede the natural breakdown process.

- Avoiding Harmful Additives: Some additives used in conventional plastics can impede biodegradability. By eschewing harmful additives and substituting them with environmentally friendly alternatives, designers enhance the end product's ability to decompose naturally.

- Modular Design: This mode of design allows products to be dismantled into individual components, each following its unique decomposition trajectory. This approach not only facilitates recycling but also enables each element to return to the natural cycle.

- Packaging Innovations: The revolution in packaging is a testament to designing for decomposition. Biodegradable and compostable packaging materials reduce the environmental footprint of single-use items. After their primary use, these materials become nutrients for the soil, fostering a circular approach to packaging.

While designing for decomposition presents an optimistic pathway towards a more sustainable future, it is important to acknowledge the complexities that accompany this approach. Educating consumers about proper disposal methods is not only a necessity but a fundamental aspect of the success of biodegradable materials. Without clear guidance and understanding, these materials may not realize their full potential in reducing environmental impact. Equally crucial is the need for widespread access to composting and recycling facilities. Effective decomposition relies on the presence of appropriate infrastructure that allows products and materials to naturally break down without harming the environment. The availability and accessibility of these facilities can vary significantly depending on geographical location and local regulations, emphasizing the need for coordinated efforts on a global scale.

The quest for decomposition must navigate a delicate equilibrium between performance and sustainability. While designing products that seamlessly decompose is a laudable goal, it cannot come at the expense of durability, functionality, or safety. Striking this balance requires a nuanced approach that draws upon the expertise of material scientists, designers, and engineers. For instance, in sectors where product longevity is paramount, such as electronics and construction, ensuring that the decomposition process aligns with safety and efficiency considerations is a formidable challenge.

As the world gravitates towards designing for decomposition, these challenges serve as opportunities for innovation, collaboration, and systemic change. Addressing them requires not only technological advancements but also a collective effort from governments, industries, consumers, and environmental advocates. By recognizing these complexities and collectively working to overcome them, we can unlock the full potential of designing for decomposition and usher in a new era of sustainable design and consumption.

The transformative potential of designing for decomposition emerges as a powerful incentive for interdisciplinary collaboration. As we stand at the crossroads of environmental urgency and creative ingenuity, designers, material scientists, engineers, and waste management experts are joining forces to craft solutions that align with circular economy principles. This convergence of expertise is essential in developing materials and products that not only meet functional requirements but also adhere to sustainability mandates. Collaborative efforts spark innovative thinking, spurring the creation of materials engineered for both performance and environmentally responsible end-of-life cycles.

Scientists and researchers are pioneering new materials, refining existing ones, and devising processes that support natural decomposition. These advancements are instrumental in crafting alternatives to conventional plastics, ensuring that the transition to sustainable materials is not a compromise on quality or utility. As materials become more biodegradable, compostable, and eco-friendly, the possibilities for designing products that integrate seamlessly into nature's cycles expand, embodying a harmonious alliance between technology and ecology.

Embracing a circular economy mindset is essential. This involves envisioning products not as linear entities but as contributors to a closed-loop system. By focusing on the end of a product's life cycle from the initial design phase, we can redirect our consumption patterns towards a more sustainable trajectory.

The urgency of plastic pollution demands innovative solutions that extend beyond superficial changes. Designing for decomposition offers a comprehensive approach that tackles the root issue—the long-lasting impact of plastic waste. As industries, designers, and consumers embrace this concept, we pave the way for a circular future where products are designed with their complete life cycle in mind. By weaving principles like material selection, simplified design, and modular components into our design ethos, we stand on the brink of an instrumental shift in how we interact with materials and products. As we step onto this path, designing for decomposition becomes more than a strategy—it becomes a commitment to mitigating plastic pollution and crafting a more sustainable world for generations to come.