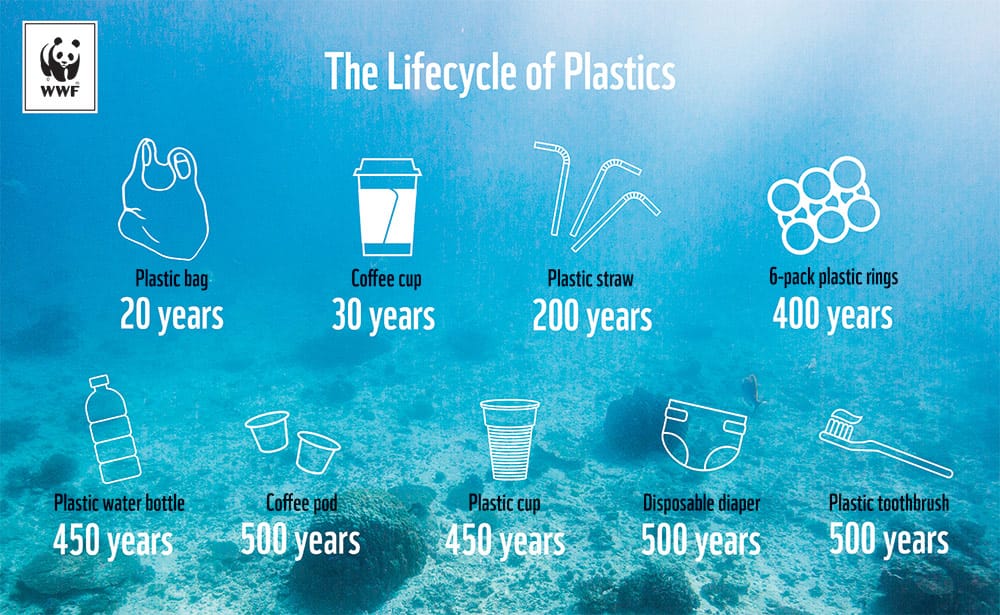

Each year, humanity churns out over 460 million metric tons of plastic. Grocery bags, bubble wrap, takeaway containers—most of it destined for a one-way trip to the landfill, the incinerator, or, more troublingly, the ocean. Once there, it lingers for centuries, breaking down not into nothingness, but into insidious microplastics that leach into food chains and the bloodstream of the planet itself.

Recycling? Nice idea, terrible execution. Fewer than 10% of plastics actually get recycled. The rest persists. And while the term “biodegradable” might ease a guilty conscience, in reality, many so-called biodegradable plastics like PLA (polylactic acid) require industrial composting conditions and remain virtually inert in marine environments. The result? A global problem that’s growing as fast as the demand for cheap, durable materials.

Enter a new breed of plastic that flips the script.

Designed to Disappear

At Japan’s RIKEN Center for Emergent Matter Science (CEMS), a team led by Professor Takuzo Aida has developed a supramolecular plastic that doesn’t just mimic the strength and flexibility of conventional polymers—it disappears completely in seawater. No microplastics. No toxic residue. Just a clean break from the long-lived pollution that’s choked oceans for decades.

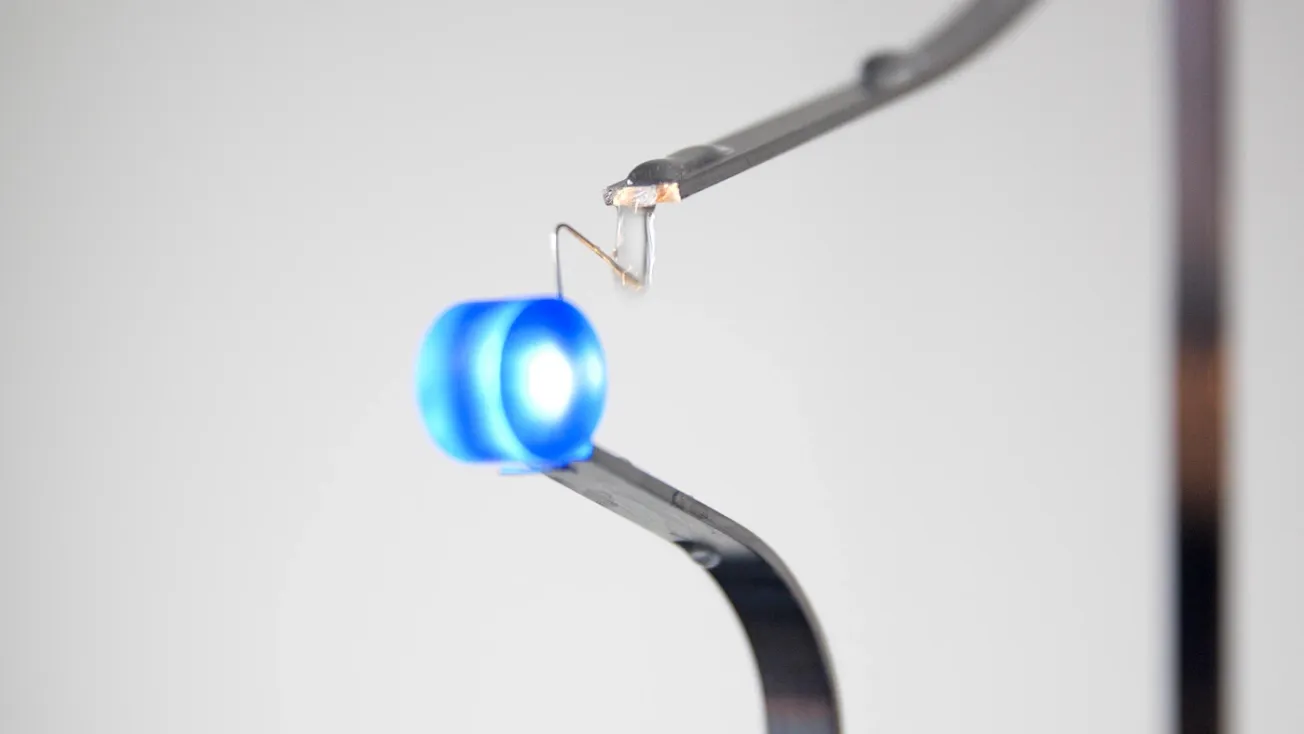

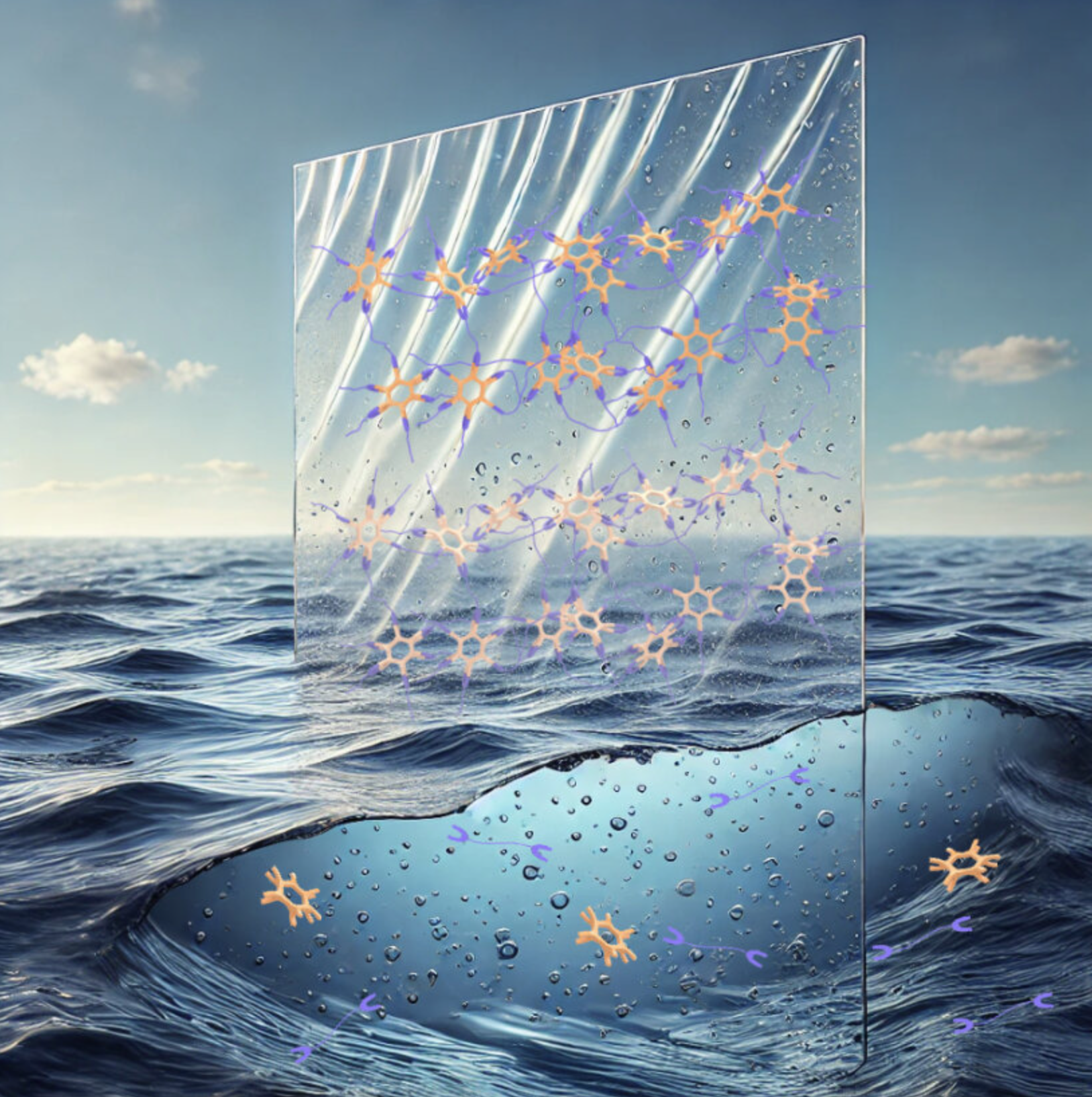

The magic behind the material is supramolecular chemistry: a field that relies on reversible, non-covalent interactions to create materials that can assemble and disassemble on cue. Think of it as building Lego structures that can fall apart under the right environmental conditions, leaving behind nothing harmful. These new plastics are held together not by permanent bonds, but by ionic salt bridges formed between guanidinium-based monomers and sodium hexametaphosphate—a food-safe additive.

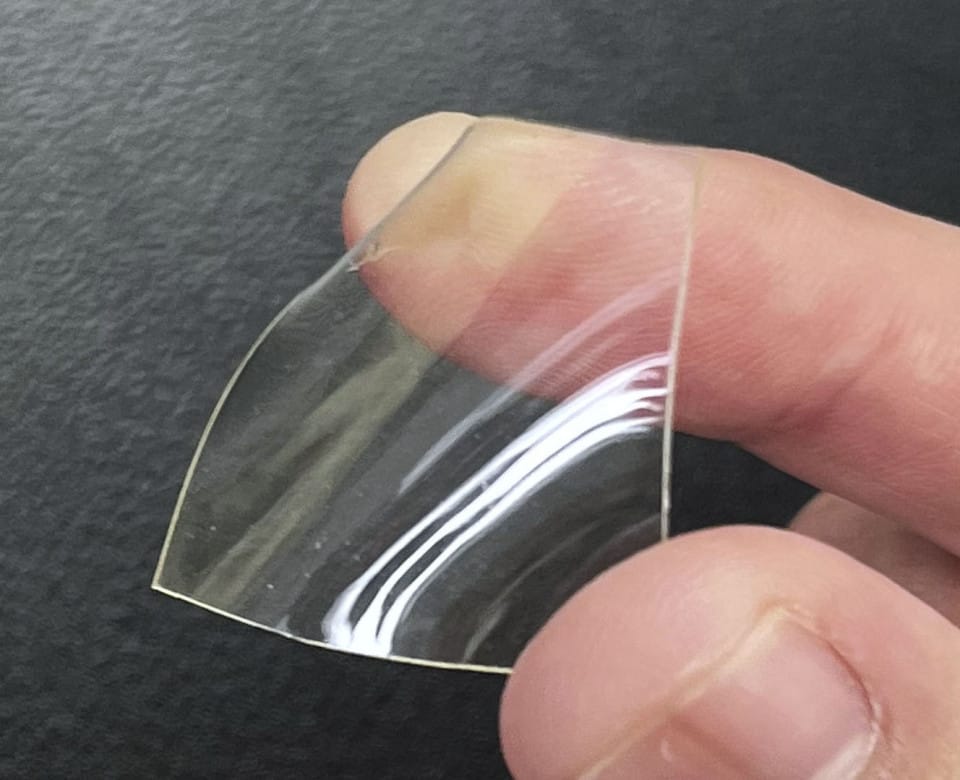

The result is a transparent, thermoplastic-like material that’s robust in everyday use but undergoes complete breakdown when exposed to seawater. The ocean’s salt ions disrupt the molecular interactions holding the plastic together, triggering its disassembly into simple, metabolizable compounds. It’s not “breaking down” in the way conventional plastics fragment. It’s disappearing at the molecular level.

A pivotal part of the process is what's called “desalting.” During synthesis, the monomer mix separates into two layers. The top: saltwater. The bottom: a dense, gooey substance full of supramolecular networks. Remove the salt, dry the goo, and you get a hard, glassy plastic. Skip desalting, and it turns brittle. In other words, salt is both the secret sauce and the off-switch.

Strong, Safe, and Infinitely Recyclable

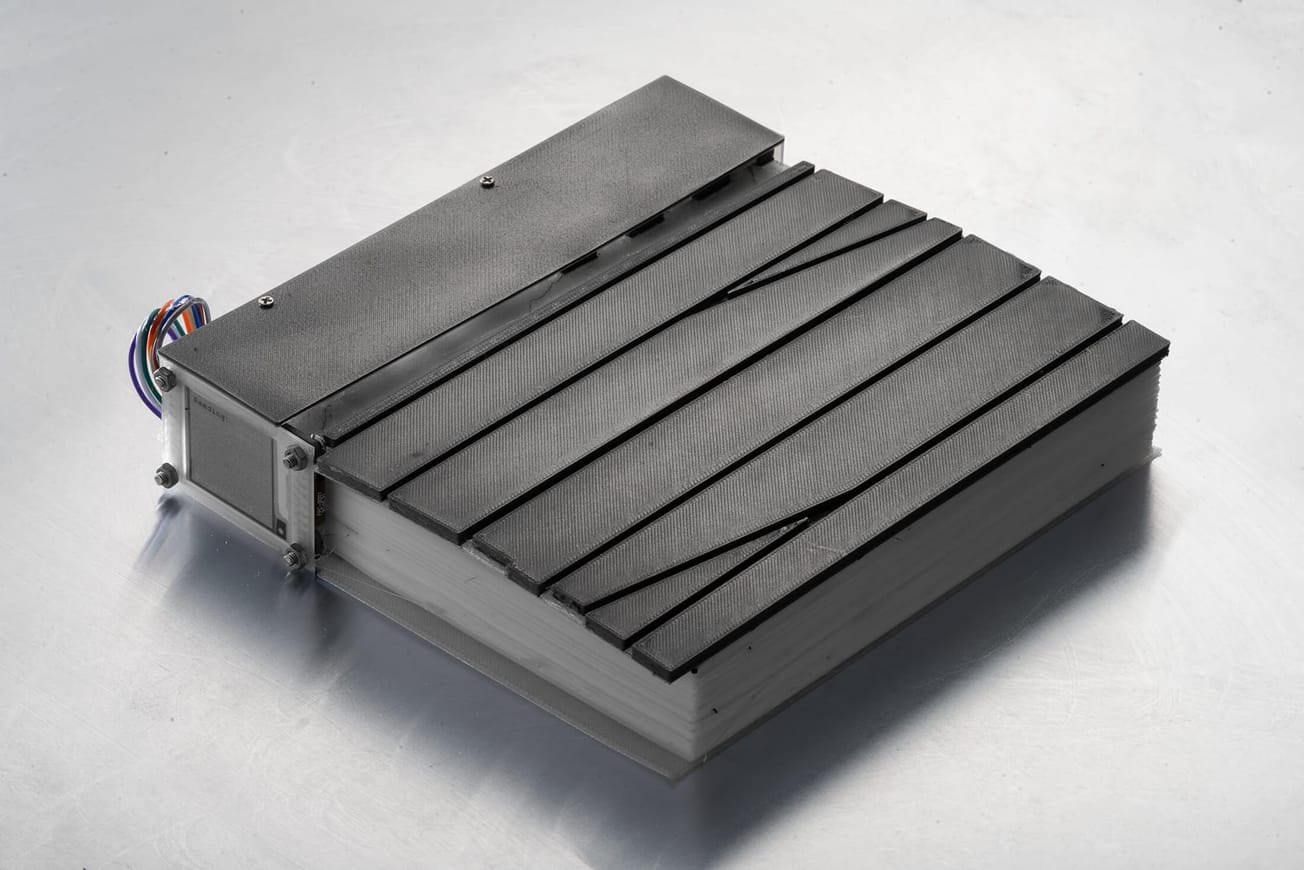

This novel plastic isn’t just biodegradable—it’s built for performance. It’s non-toxic, non-flammable, and heat-moldable above 120°C. By tweaking its building blocks, researchers can tailor its properties for different uses: rigid and glass-like for durable goods, soft and elastic for flexible packaging, even medical-grade materials for drug delivery systems.

But perhaps the most mind-blowing feature is its recyclability. Unlike traditional plastics that degrade with each cycle, supramolecular plastics can be broken down and rebuilt with minimal energy. After being dissolved, up to 91% of the original materials can be recovered as powders and reused. That means a single batch of plastic could theoretically live infinite lives, without ever becoming waste.

In soil, the story’s even better. The plastic decomposes entirely within ten days, releasing nitrogen and phosphorus—elements that act more like plant food than pollutants. In the sea, it’s equally efficient, vanishing without harming marine life or accumulating in sediment.

From Breakthrough to Reality

Of course, there are hurdles. Scaling production of supramolecular plastics is still costly—up to five times more than standard polyethylene. But researchers are betting that as demand for eco-friendly materials grows and green regulations tighten, economies of scale will bring prices down. It happened with solar panels and electric vehicles. Plastics could be next.

Durability also remains a concern. While early prototypes are impressively strong, they don’t yet match industrial plastics in extreme environments. Future iterations—and industry partnerships—will be key to expanding its use beyond niche applications.

Still, the potential is revolutionary. For over a century, we’ve designed plastics for permanence. Now, for the first time, we’re designing them for graceful, complete disappearance. Not by accident. Not by degradation. But by intelligent design.

A plastic that heals the material lifecycle instead of breaking it.

A plastic that lives only as long as it’s needed.

A plastic that—when its job is done—says goodbye.