Soft robotics, a field that draws inspiration from biological organisms to create flexible and adaptable robots, has been steadily advancing over the years. One of the key components driving innovation in soft robotics is the integration of fluid circuits, which offer unique advantages in terms of flexibility, versatility, and efficiency. The current state of research and usage of fluid circuits in soft robotics is still in its relative infancy; however, recent advancements in fluid circuit technology with haptic feedback capabilities have further expanded the possibilities of this technology. The applications for soft robotics exist across industries, from healthcare to industrial automation.

Soft robotics has emerged as a promising area of research due to its potential to overcome the limitations of traditional rigid robotics in various applications. Unlike traditional robots, soft robots are made from flexible materials and can mimic the movement and behavior of natural organisms. This flexibility enables them to navigate complex environments, interact safely with humans, and perform tasks that are challenging for rigid robots.

One key advancement in soft robotics is the integration of fluid circuits, which utilize the flow of liquids or gases to control the movement and functionality of soft robotic systems. Fluid circuits consist of channels or chambers filled with fluid that can be manipulated to achieve desired motions or actions. Depending on the specific application requirements, these circuits can be embedded within the soft robot's structure or attached externally.

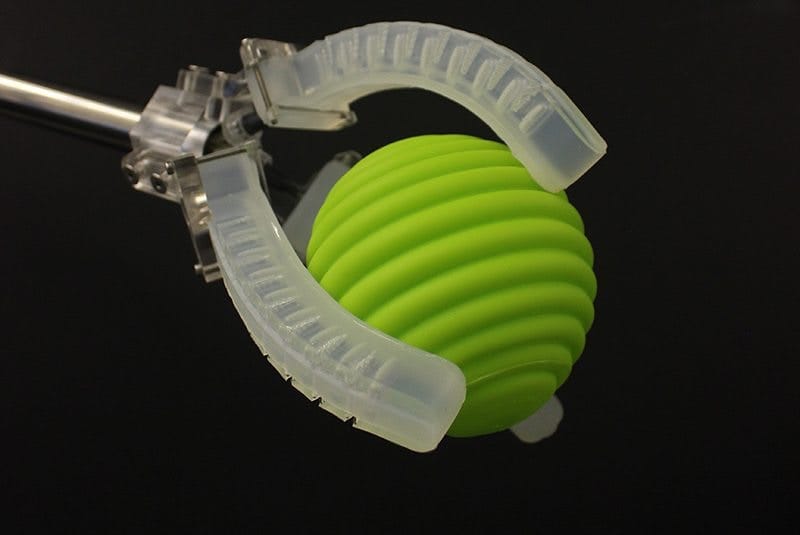

The applications of fluid circuits in soft robotics are diverse and span a wide range of industries. In biomedical applications, fluid circuits are used to create soft robotic devices for minimally invasive surgery, drug delivery, and prosthetics. The flexibility and controllability of fluid circuits make them ideal for navigating delicate tissues and structures within the human body, offering new possibilities for medical interventions. In industrial automation, fluid circuits are employed in soft robotic grippers, manipulators, and actuators for tasks such as handling fragile objects, assembly, and inspection. The ability to precisely control the flow of fluid enables soft robots to grasp and manipulate objects of varying shapes, sizes, and materials, making them suitable for a wide range of manufacturing applications.

Researchers have developed novel materials and fabrication techniques to enhance the performance and durability of fluid circuits, paving the way for more robust and reliable soft robotic systems. Additionally, advancements in control algorithms and sensing technologies have enabled finer control and feedback mechanisms, improving the accuracy and efficiency of fluid-based soft robots.

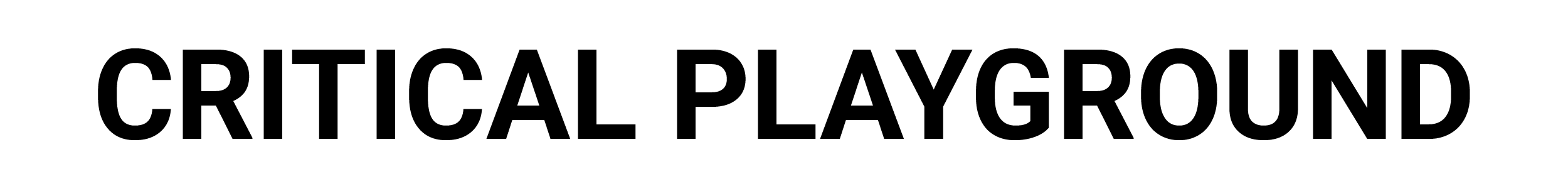

Image Credit: Cornell University, Kirstin Petersen, Collective Embodied Intelligence Lab

A team of researchers at Cornell University, led by Kirstin Petersen, an assistant professor of electrical and computer engineering, has devised a novel system of fluid-driven actuators, facilitating soft robots to execute more intricate motions. The design harnesses viscosity, a factor previously hindering the mobility of such robots. Petersen's Collective Embodied Intelligence Lab has been investigating methods to transfer a robot's cognitive functions and behaviors from its "brain" to its body, utilizing the robot's mechanical reflexes and its ability to interact with its surroundings. By minimizing the reliance on explicit computation, the robot can be simplified, enhanced in durability, and rendered more cost-effective to produce. According to Petersen, “Most soft robots these days are fluid-driven. In the past, most people have looked at how we could get extra bang for our bucks by embedding functionality into the robot material, like the elastomer. Instead, we asked ourselves how we could do more with less by utilizing how the fluid interacts with that material.”

MotorSkins, a company specializing in textile-based wearable robotics, incorporates fluid logic with haptic interfaces in reactive textiles for tactile and sensory feedback. The specific design of the fluid circuits integrated into the multilayered material structures of their hydrodynamic apparel enables the apparel to sense and respond to its surroundings. The reactive textile actuators will change shape, adapting their form based on external stimuli, such as a user’s touch.

Image Credit: MotorSkins

Image Credit: MotorSkins

Looking ahead, the future of fluid circuits in soft robotics holds great promise. Continued research and development efforts are expected to lead to further innovations in fluid circuit design, materials, and integration techniques. As the field continues to mature, we can anticipate the emergence of new applications and use cases for fluid-based soft robots across a wide range of domains, from healthcare and manufacturing to search and rescue operations and beyond.