Researchers at The University of Texas at Austin, working with Sandia National Laboratories and other U.S. laboratories, have developed a 3D printing technique that enables fine-grained control over the internal structure of thermoplastics. The method, called Crystallinity Regulation in Additive Fabrication of Thermoplastics (CRAFT), allows printed objects to vary in stiffness, flexibility, and optical properties within a single material system.

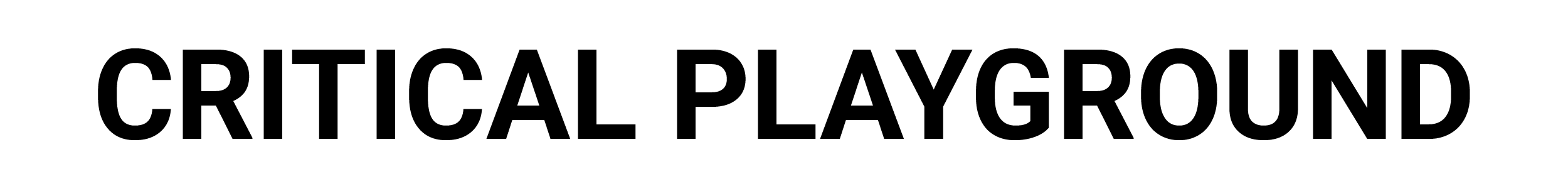

CRAFT uses digital light processing (DLP) 3D printing and a widely available liquid resin, cyclooctene, that can be polymerized and crystallized in a controlled manner. By modulating grayscale light patterns during printing, the researchers adjust the degree of crystallinity at specific locations inside the object. Because crystallinity directly influences mechanical performance, this approach enables spatial tuning of properties without switching materials or print heads.

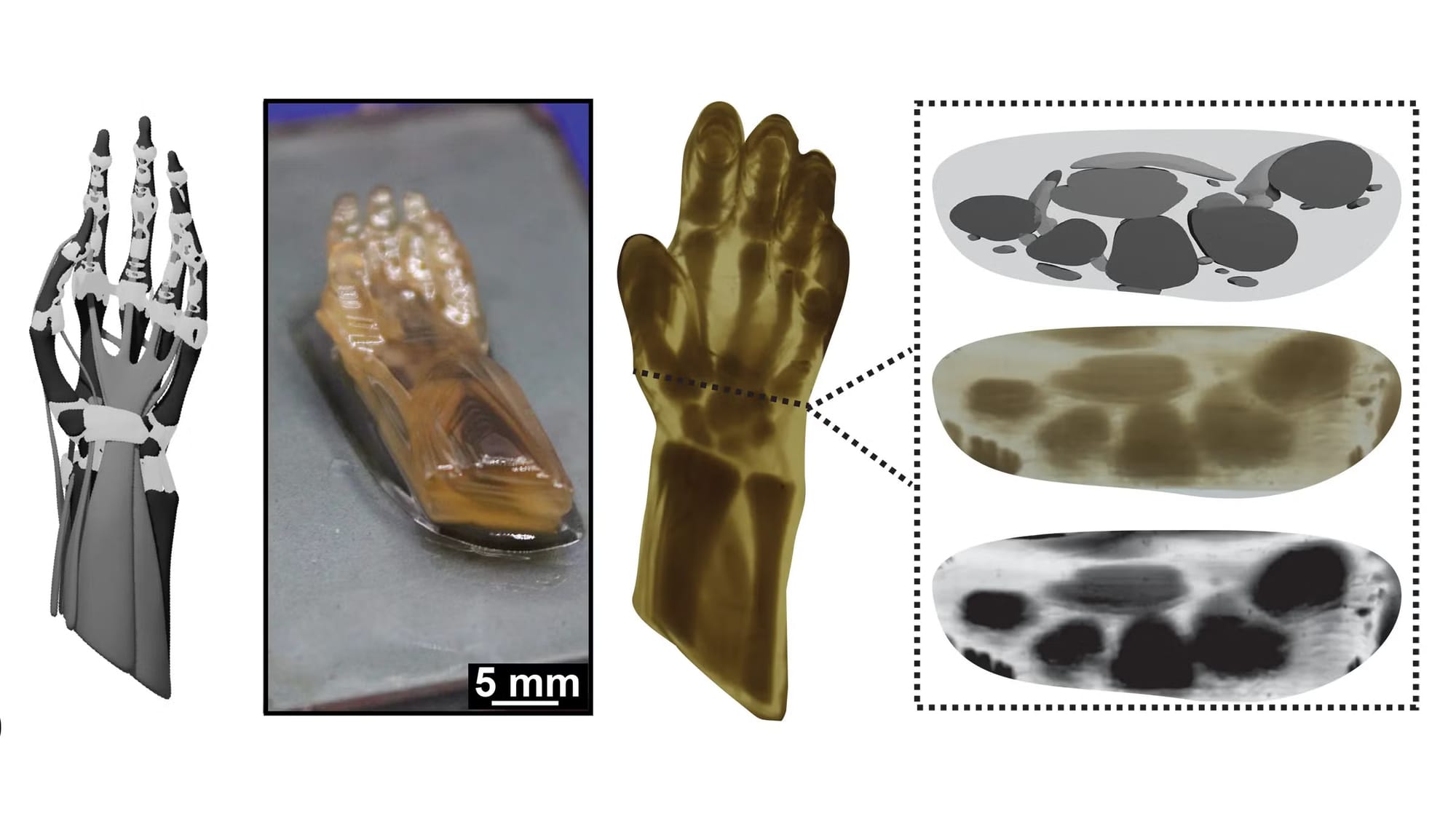

In demonstrations reported by the university, the team fabricated a model human hand with regionally differentiated mechanical behavior, approximating the relative rigidity of bone and the flexibility of surrounding tissues such as ligaments and tendons. A grayscale design controlled light intensity during printing, producing distinct crystalline and amorphous domains within a single feedstock material. Traditional multi-material 3D printing can achieve visual complexity by combining different inks, but these materials often adhere poorly at their interfaces, leading to structural weaknesses. The CRAFT method instead varies properties by regulating crystallinity during fabrication, eliminating the need to bond dissimilar materials and reducing interfacial failure.

The technique is compatible with commercially available digital light processing (DLP) or LCD printers capable of grayscale projection, including relatively low-cost systems. According to the university, potential applications include anatomical training models for medical education and energy-damping structures such as personal protective gear. The researchers also point to bioinspired materials with alternating hard and soft regions, similar to structures found in bone or tree bark, as another area of exploration. By enabling spatial control over mechanical and optical properties within a single printed object, CRAFT extends additive manufacturing beyond geometric complexity toward internal structural differentiation.